Does a Manual Transmission Have a Torque Converter? ‒ An In-Depth Look

The question of whether a manual transmission can utilize a torque converter is complex, defying simple answers․ While traditionally separate, combining them offers unique benefits in specific, extreme applications, like high-performance builds․

The automotive world presents a fascinating array of transmission technologies, each designed to efficiently transfer power from the engine to the wheels․ Traditionally, these fall into two primary categories: manual and automatic transmissions․ Manual transmissions, the older of the two, require the driver to manually select gears using a clutch pedal and a gear stick, offering a direct mechanical connection between the engine and the drivetrain․

Automatic transmissions, conversely, handle gear changes automatically, utilizing a fluid coupling – the torque converter – to manage power delivery․ However, the landscape is evolving, with the emergence of Continuously Variable Transmissions (CVTs) and sequential manual transmissions blurring the lines․ Despite these advancements, the conventional automatic remains a popular choice, particularly among enthusiasts․ The core difference lies in how power is managed and transferred; manuals prioritize driver control, while automatics emphasize convenience and ease of use․

Interestingly, the discussion around torque converters often centers on automatic transmissions, but the possibility of integrating them with manual systems is gaining traction in specialized applications․ This exploration stems from a desire to leverage the benefits of both technologies – the control of a manual with the torque multiplication and smoothness of a torque converter․ Understanding these fundamental transmission types is crucial before delving into the intricacies of combining a manual transmission with a torque converter․

What is a Torque Converter?

A torque converter is a type of fluid coupling that allows the engine to spin somewhat independently of the transmission․ It’s a crucial component in most automatic transmissions, acting as a bridge between the engine and the gearbox․ Unlike a direct mechanical connection, the torque converter uses fluid – typically automatic transmission fluid (ATF) – to transmit rotational power․

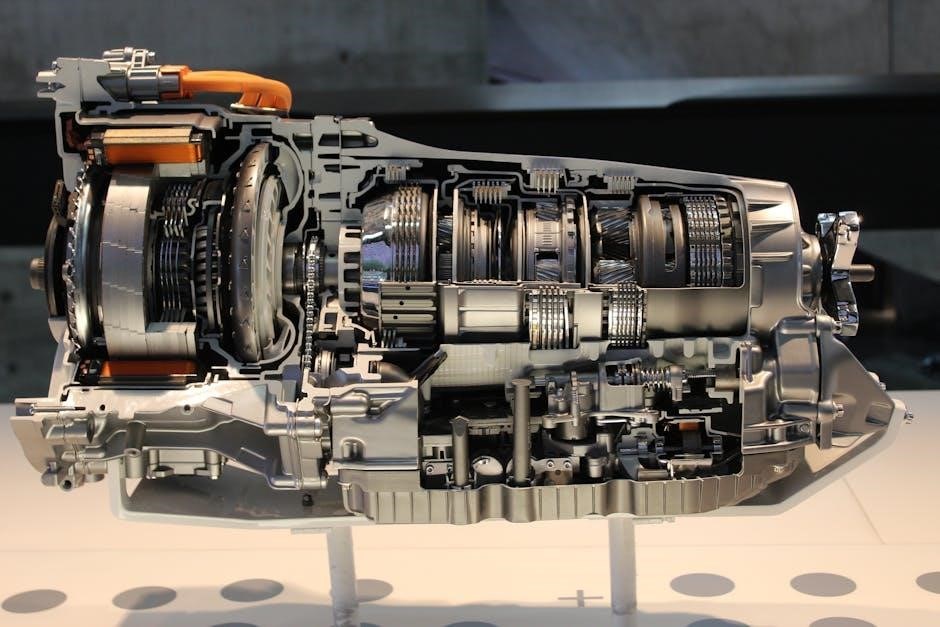

This fluid coupling consists of three main components: the impeller (pump), the turbine, and the stator․ The impeller, driven by the engine, spins and pumps fluid towards the turbine, which is connected to the transmission input shaft․ As the fluid impacts the turbine blades, it causes it to rotate, transferring power․ The stator, positioned between the impeller and turbine, redirects fluid flow, multiplying torque, especially at lower engine speeds․

This torque multiplication is a key advantage of torque converters, providing increased power during acceleration․ However, without a lock-up mechanism, some energy is lost due to fluid slippage․ Modern torque converters often incorporate a lock-up clutch, which mechanically connects the impeller and turbine at cruising speeds, improving efficiency․ Essentially, it’s a sophisticated hydraulic system designed to smoothly and efficiently transfer engine power to the transmission․

The Core Difference: Manual vs․ Automatic Transmissions

The fundamental distinction between manual and automatic transmissions lies in how power is transferred from the engine to the wheels․ Manual transmissions rely on a direct mechanical linkage – gears that the driver selects using a clutch pedal and shift lever․ This provides a solid, efficient connection, but requires driver intervention to change gears․

Automatic transmissions, conversely, utilize a torque converter and planetary gearsets to automatically select the appropriate gear ratio․ The torque converter allows for smooth, continuous power delivery without the need for a clutch pedal․ This simplifies operation, but traditionally introduces some efficiency losses due to fluid slippage within the torque converter․

Manual transmissions offer the driver complete control over engine RPM and gear selection, enabling precise driving and potentially better fuel economy․ Automatic transmissions prioritize convenience and ease of use․ However, modern automatics with lock-up torque converters and advanced control systems have significantly narrowed the efficiency gap․ The choice often comes down to driver preference and intended application․

Torque Converters and Automatic Transmissions

Torque converters are integral to automatic transmissions, employing fluid coupling to transmit engine power․ They also offer torque multiplication, enhancing low-speed acceleration and smooth operation․

How Torque Converters Work: Fluid Coupling and Multiplication

A torque converter fundamentally operates as a fluid coupling device, utilizing transmission fluid to transfer rotational power from the engine to the automatic transmission․ It consists of three primary components: the impeller (or pump), the turbine, and the stator․ The impeller, connected to the engine’s crankshaft, spins and throws fluid against the turbine, which is connected to the transmission’s input shaft․

This fluid transfer initiates turbine rotation, effectively transmitting power․ However, the key to a torque converter’s functionality lies in its ability to multiply torque․ This multiplication occurs due to the interaction between the fluid flow and the stator․ The stator redirects the fluid returning from the turbine back to the impeller at an angle, increasing the force applied to the turbine․

This process is most effective at lower engine speeds, where a greater torque multiplication is needed to overcome inertia and accelerate the vehicle․ As vehicle speed increases, the difference in speed between the impeller and turbine diminishes, reducing torque multiplication․ Modern torque converters often include a lock-up clutch, which mechanically connects the impeller and turbine at cruising speeds, eliminating fluid slippage and improving efficiency․

Essentially, the torque converter allows the engine to continue running even when the vehicle is stopped, preventing stalling, and provides a smoother, more comfortable driving experience compared to a traditional manual transmission․

Lock-Up Torque Converters: Improving Efficiency

Traditional torque converters, while providing smooth power delivery, inherently suffer from some degree of slippage between the impeller and turbine․ This slippage, though necessary for initial acceleration and preventing stalling, results in energy loss and reduced fuel efficiency, particularly at higher, consistent speeds․ Lock-up torque converters address this issue by incorporating a mechanical clutch that directly connects the impeller and turbine․

When activated, typically by the transmission control module (TCM) at cruising speeds, the lock-up clutch eliminates the fluid coupling, creating a solid connection․ This effectively removes slippage, maximizing power transfer and significantly improving fuel economy․ The TCM monitors various parameters, such as vehicle speed, throttle position, and engine load, to determine the optimal time to engage and disengage the lock-up clutch․

Without a lock-up feature, the continuous circulation of fluid within the torque converter generates heat and reduces overall drivetrain efficiency․ The lock-up mechanism minimizes these drawbacks, offering a more direct and efficient driving experience․ It’s a crucial advancement in automatic transmission technology, bridging the gap in efficiency between automatics and manuals․

Hydraulic solenoids and an internal pump within the transmission typically control the lock-up function, ensuring smooth and reliable operation․

The Role of the Torque Converter in Automatic Shifting

In automatic transmissions, the torque converter isn’t merely a power transfer device; it’s integral to the shifting process itself․ It acts as a hydraulic coupling, allowing the engine to continue running even when the wheels are stopped, and facilitates smooth transitions between gears․ The torque converter’s internal design, featuring an impeller, turbine, and stator, plays a crucial role in multiplying torque, especially during initial acceleration․

As the vehicle gains speed and the transmission shifts, the torque converter’s internal components adjust to maintain optimal efficiency․ The TCM utilizes sensors to monitor vehicle speed, engine load, and throttle position, then commands the transmission to shift accordingly․ The torque converter responds by altering the fluid flow, enabling a seamless gear change without interrupting power delivery․

The ability of the torque converter to ‘slip’ allows for a cushioned shift feel, preventing harsh jolts․ Modern torque converters, equipped with lock-up clutches, further refine this process by providing a direct mechanical connection at cruising speeds, enhancing efficiency and responsiveness․ Without the torque converter, automatic shifting would be abrupt and inefficient․

Essentially, it’s the hydraulic heart of the automatic transmission, orchestrating smooth and efficient gear changes․

Manual Transmissions: A Different Approach

Unlike automatics, traditional manual transmissions rely on a direct mechanical connection via gears and a clutch․ They don’t inherently need a torque converter for operation or power transfer․

How Manual Transmissions Work: Gears and Clutch

Manual transmissions operate on a fundamentally different principle than automatics, relying on a driver-controlled system of gears to alter the engine’s output․ The core components are a set of gears with varying ratios and a clutch mechanism․ The engine’s power is initially sent to the clutch, a device that engages and disengages the connection between the engine and the transmission․

When the clutch pedal is pressed, the connection is broken, allowing the driver to select a different gear․ This selection changes the gear ratio, impacting both speed and torque․ Lower gears provide more torque for acceleration and climbing hills, while higher gears offer better fuel efficiency at cruising speeds․ The driver manually synchronizes engine speed with the selected gear using the clutch and shifter․

This direct mechanical linkage is a key distinction from automatic transmissions, which utilize a torque converter for fluid coupling․ The precise control offered by a manual transmission allows for a more direct and engaging driving experience, but requires greater driver skill and coordination․ The simplicity of the system also contributes to its generally higher reliability and lower maintenance costs compared to automatics․

The Clutch’s Function: Disconnecting and Reconnecting Power

The clutch is the pivotal component enabling gear changes in a manual transmission․ Its primary function is to temporarily disconnect the engine’s power from the transmission, allowing the driver to smoothly select a different gear ratio without damaging the drivetrain․ When the clutch pedal is depressed, it disengages a pressure plate, separating the friction disc from the engine’s flywheel․

This separation interrupts the power flow, enabling the driver to shift gears․ Releasing the clutch pedal gradually re-engages the pressure plate, clamping the friction disc against the flywheel and re-establishing the connection between the engine and transmission․ This process requires precise coordination to avoid jerking or stalling the engine․

The clutch’s ability to smoothly disconnect and reconnect power is crucial for efficient and controlled driving․ It allows the driver to match engine speed to the desired gear, optimizing performance and fuel economy․ Without a functioning clutch, shifting gears in a manual transmission would be impossible, highlighting its central role in the system’s operation․

Manual Transmissions and Engine Braking

Manual transmissions excel in engine braking, a technique utilizing the engine’s resistance to slow the vehicle․ Downshifting to a lower gear increases the engine’s RPMs, creating a braking force that supplements the vehicle’s traditional brakes․ This is particularly useful on long descents, reducing brake wear and maintaining control․

Unlike automatic transmissions with torque converters, manual transmissions offer a direct mechanical connection between the engine and wheels when the clutch is engaged․ This direct link maximizes the engine braking effect, providing more substantial deceleration․ Skilled drivers can precisely control the engine’s speed through downshifting, effectively managing the vehicle’s momentum․

The absence of a torque converter’s fluid coupling in a manual system means less energy is lost during engine braking․ This translates to a more efficient and responsive braking experience․ While modern automatics with lock-up torque converters mitigate some of this difference, manual transmissions still generally provide superior engine braking capabilities, favored by performance drivers and those navigating challenging terrain․

Can a Manual Transmission Utilize a Torque Converter?

Yes, it’s possible! Though unconventional, a torque converter can be paired with a manual transmission, particularly in extreme applications, offering torque multiplication and smoothing power delivery․

Applications of Torque Converters with Manual Transmissions

The integration of a torque converter with a manual transmission isn’t common in standard vehicles, but finds a niche in specialized applications․ Historically, this setup emerged as builders sought to replicate the launch characteristics of early automatic transmissions in drag racing, specifically with classic Mopar “Max Wedge” and “Race Hemi” engines․

These early automatic designs, before sophisticated lock-up converters, benefited from the torque multiplication offered by the converter․ Modern applications continue this trend, particularly in high-horsepower builds where maximizing off-the-line acceleration is crucial․ The torque converter allows for a softer launch, reducing stress on the drivetrain․

Furthermore, this combination can be advantageous in off-road vehicles or those requiring precise low-speed control․ The torque converter’s fluid coupling provides a smoother, more manageable power delivery in challenging terrain․ It’s also seen in some custom builds aiming for a unique driving experience, blending the control of a manual with the launch assistance of an automatic․ However, it’s important to note that this is generally reserved for enthusiasts and specialized builds, not factory production vehicles․

Benefits of Combining a Torque Converter with a Manual Transmission

The primary benefit of pairing a torque converter with a manual transmission lies in enhanced launch capabilities, particularly for high-performance applications․ The torque converter’s inherent torque multiplication provides a significant advantage off the line, allowing for smoother, more controlled acceleration․ This is especially valuable in drag racing or situations demanding rapid starts․

Beyond launch control, the fluid coupling of the torque converter cushions the drivetrain from shock loads, reducing stress on gears and axles․ This can improve component durability, particularly in high-horsepower scenarios․ It also offers a degree of smoothness not typically found in a traditional manual setup, making low-speed maneuvering easier and more forgiving․

Additionally, the torque converter can aid in engine braking, though not to the same extent as a fully synchronized manual transmission; While a lock-up converter improves efficiency, the fluid coupling still provides a damping effect․ Ultimately, this combination offers a unique blend of control and performance, appealing to enthusiasts seeking a customized driving experience․

Drawbacks and Considerations

Despite the performance benefits, integrating a torque converter with a manual transmission introduces several drawbacks․ The most significant is complexity and cost; retrofitting requires substantial modification and specialized components, increasing the overall expense; Weight is also a concern, as torque converters are considerably heavier than a traditional clutch setup – roughly double the weight, adding to the vehicle’s overall mass․

Efficiency can be compromised if the torque converter isn’t equipped with a lock-up function․ Without locking, some power is lost due to fluid slippage, reducing fuel economy and overall drivetrain efficiency․ Even with lock-up, achieving the same level of responsiveness as a direct mechanical connection is challenging․

Furthermore, the added complexity can introduce potential failure points, requiring more frequent maintenance and specialized expertise for repairs․ It’s crucial to carefully evaluate the trade-offs and ensure the benefits outweigh the added complexity and potential downsides before pursuing this unconventional setup․

Historical Context: Automatics with Clutch Systems

Early automatic transmissions sometimes employed clutch systems instead of torque converters, predating widespread torque converter technology․ These designs aimed for smoother shifting before efficient converters were available․

Early Automatic Transmission Designs

The earliest iterations of automatic transmissions, emerging before the dominance of the torque converter, often sought to replicate the convenience of automatic shifting without relying on fluid coupling․ These pioneering designs frequently incorporated mechanical clutch systems, mirroring aspects of manual transmissions but automating the engagement and disengagement process․

Instead of a torque converter’s fluid dynamics, these early automatics utilized complex arrangements of planetary gearsets and multiple clutches․ These clutches were controlled by hydraulic or mechanical means, responding to vehicle speed and engine load to select the appropriate gear ratio․ The goal was to provide a seamless driving experience, eliminating the need for the driver to manually operate a clutch pedal and shift gears․

However, these early systems were often less efficient and more mechanically complex than later torque converter-based automatics․ They could be prone to harsh shifting and lacked the torque multiplication benefits offered by fluid coupling․ Despite these drawbacks, they represented a crucial stepping stone in the evolution of automatic transmission technology, paving the way for the more refined and efficient systems we see today․ These systems demonstrate a historical attempt to automate gear changes without the now-standard torque converter․

The Evolution of Automatic Transmission Technology

The development of automatic transmissions witnessed a significant shift with the widespread adoption of the torque converter․ Initially, these converters were relatively simple, primarily offering fluid coupling․ However, engineers quickly recognized the potential for torque multiplication, enhancing acceleration and low-speed performance․ This led to refinements in torque converter design, incorporating stator mechanisms to amplify engine torque․

A pivotal advancement was the introduction of lock-up torque converters․ These devices mechanically couple the engine and transmission at cruising speeds, eliminating the slippage inherent in fluid coupling and dramatically improving fuel efficiency․ Simultaneously, control systems evolved from purely mechanical and hydraulic to electronically controlled, enabling smoother, more precise shifting schedules․

Modern automatic transmissions now boast eight, nine, or even ten speeds, maximizing efficiency and providing a wider range of gear ratios․ Furthermore, the integration of advanced features like adaptive learning algorithms and predictive shifting further optimizes performance․ While some explore clutch-based automatics, the torque converter remains a cornerstone, even in hybrid applications, demonstrating its enduring relevance and adaptability within the automotive landscape․

Modern Trends in Transmission Development

Contemporary transmission development showcases a fascinating interplay between established technologies and innovative approaches․ While continuously variable transmissions (CVTs) and sophisticated dual-clutch transmissions (DCTs) gain traction, the conventional automatic, often utilizing a torque converter, persists and evolves․ A key trend involves optimizing torque converter lock-up strategies for enhanced fuel economy and responsiveness․

Interestingly, a resurgence of interest exists in combining torque converters with manual transmissions, particularly in high-performance and specialized applications․ This configuration aims to leverage the torque multiplication benefits of a converter while retaining the driver control associated with a manual gearbox․ Such systems often cater to extreme builds, like restored Super Stockers, demanding unique power delivery characteristics․

Furthermore, hybridization and electrification are profoundly influencing transmission design․ Electric vehicles frequently employ single-speed gearboxes, while hybrid systems often integrate complex power-split devices․ Despite these advancements, the fundamental principles of torque management and efficient power transfer remain central, often drawing upon the legacy of torque converter technology, even in unconventional forms․